Tel : 0086-158 6576 3888 E-mail : info@huatongmachinery.com

E-mail : info@huatongmachinery.com

ONLINE MESSAGE

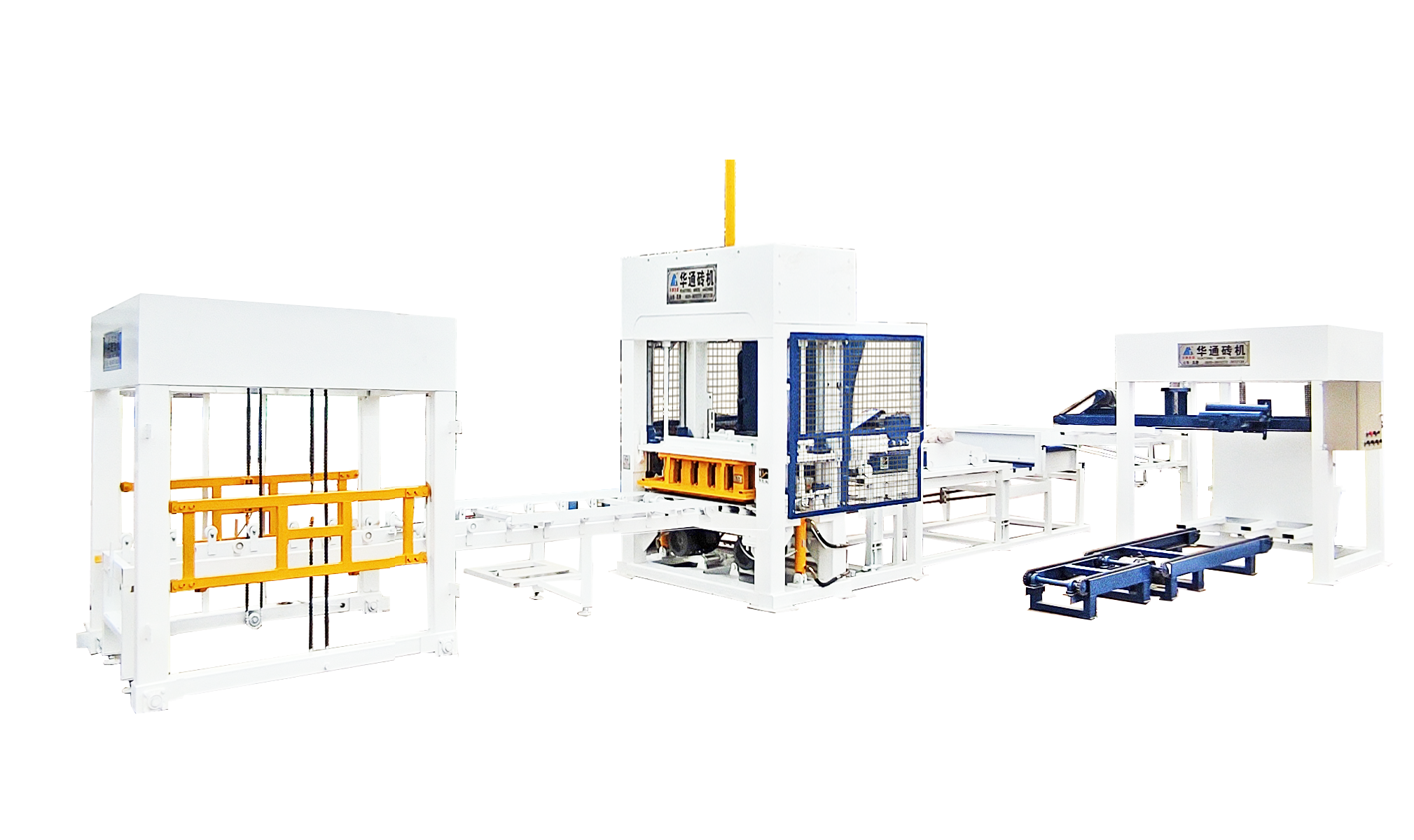

QT8-15 Automatic Block Making Machine

The machine adopts four galvanized pipe with sleeve bearing to ensure the exact movement of mould.Concrete feeder adopts orienting way operation that will decrease the friction with mould and realize perfect concrete feeding.

Key words : Concrete Block Machine

Category :

Product Series

Concrete Block Machine

QT8-15 Automatic Block Making Machine

Production Capacity of QT8-15Automatic Block Making Machine

|

Block Type |

Picture |

Size(L x W x H) |

Pcs./ Pallet |

Pcs./ Hour |

Pcs./ 8Hours |

|

Hollow Block |

|

400x200x200mm |

7.5 |

1170 |

9375 |

|

Hollow Block |

|

400x150x200mm |

8 |

1250 |

10000 |

|

Hourdi Block |

|

530x160x195mm |

6 |

940 |

7500 |

|

Solid Brick |

|

220x105x70mm |

34 |

5400 |

42500 |

|

Paving Block |

|

200x100x60mm |

30 |

4687 |

37500 |

|

Paving Block |

|

225x112.5x60mm |

20 |

2300 |

25000 |

|

We produce mould according to size and shape of client’s block. |

|||||

Technical Parameter of QT8-15Automatic Block Making Machine

|

Dimension |

3250×2000×2950mm |

|

Weight |

12000KGS |

|

Pallet Size |

1150×750mm |

|

Power |

35.7KW |

|

Mode of Vibration |

Table Vibration |

|

Vibration Frequency |

4200r/min |

|

Vibration Force |

80KN |

|

Cycle Time |

12-16 S |

Features of QT8-15Automatic Block Making Machine

1.The machine adopts four galvanized pipe with sleeve bearing to ensure the exact movement of mould.Concrete feeder adopts orienting way operation that will decrease the friction with mould and realize perfect concrete feeding.

2.The vibration system adopts German Frequency Conversion Technique.The vibration motor is Frequency Conversion Controlled.The lubrication of vibrator adopts oil immersed,which improve the using life of bearing and gear of vibrator.

3.Moulding is by table vibration and hydraulic pressure.Wet blocks made by our machine has good density.Solid blocks can be taken off pallet and save pallet cost.

4.The mould is made with heat treatments of quenching,tempering,carbonization and boriding.Working life of mould is improved.

5.The Electric Control System adopts Siemens PLC,Schneider contactor ,Omron proximity sensors.

Site Picture of QT8-15Automatic Block Making Machine

LEAVE A MESSAGE ONLINE

RELATED PRODUCTS

QT10-15 Automatic Block Making Machine

The machine adopts four galvanized pipe with sleeve bearing to ensure the exact movement of mould.Gear and shaft balance system can make male and female mould move stably.Concrete feeding is revolving,convective and compulsive to ensure block density and reduce feeding cycle. Feeder moving is two curved arms driven by two cylinders,which makes feeder move quickly,durably,and steady.

QT5-15 Automatic Block Making Machine

The machine adopts four galvanized pipe with sleeve bearing to ensure the exact movement of mould.Concrete feeder adopts orienting way operation that will decrease the friction with mould and realize perfect concrete feeding.

QT5-15 Semi-automatic Block Making Machine

The machine can produce hollow block,solid block,paving block by changing mould.Way of moulding is vibration combined with hydraulic pressure.So blocks have good strength and density. The way of concrete feeding is compulsive by four shafts with blades.It is quick speed and well distributed.The vibration is oil-immersed to have a good lubrication.

QT4-15 Semi-automatic Block Machine

The machine can produce hollow block,solid block,paving block by changing mould.Way of moulding is vibration combined with hydraulic pressure.So blocks have good strength and density.